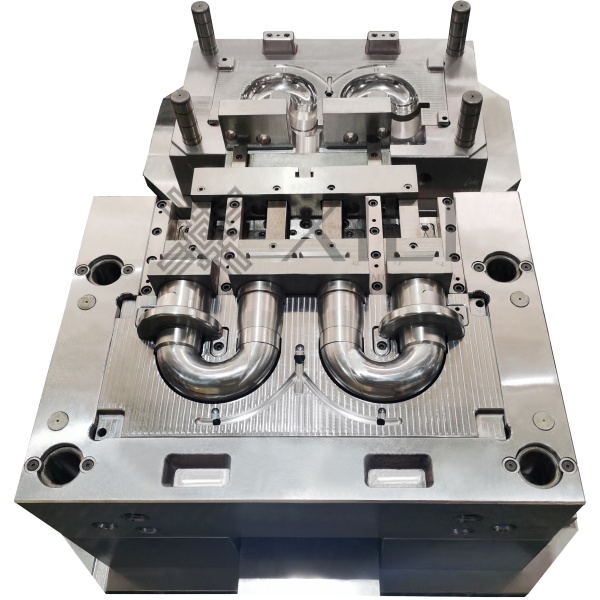

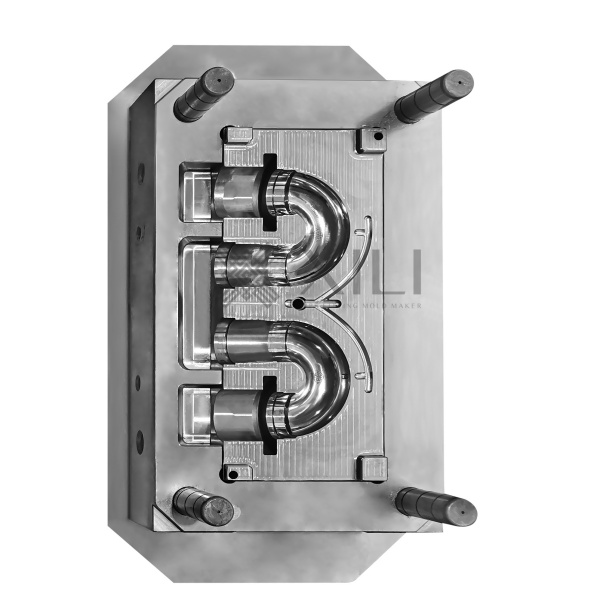

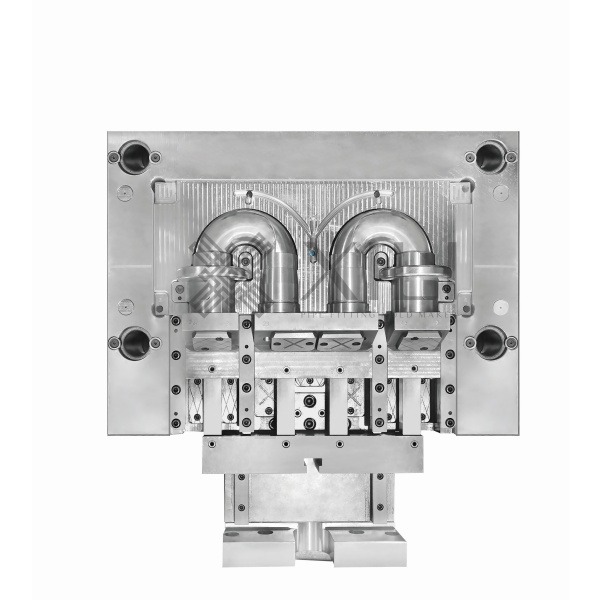

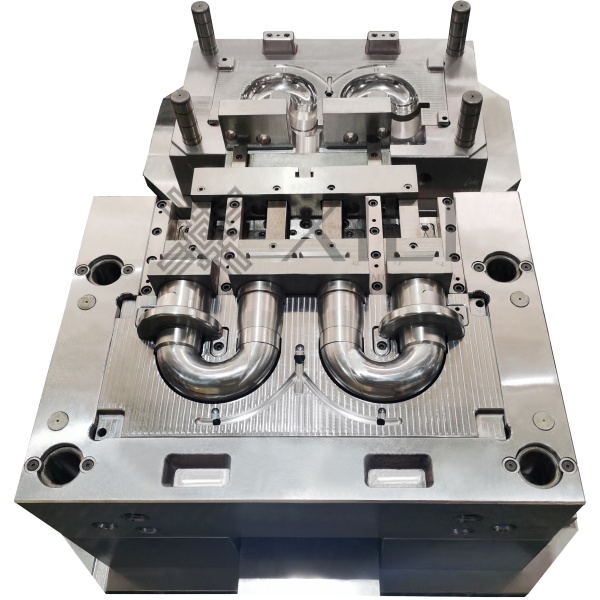

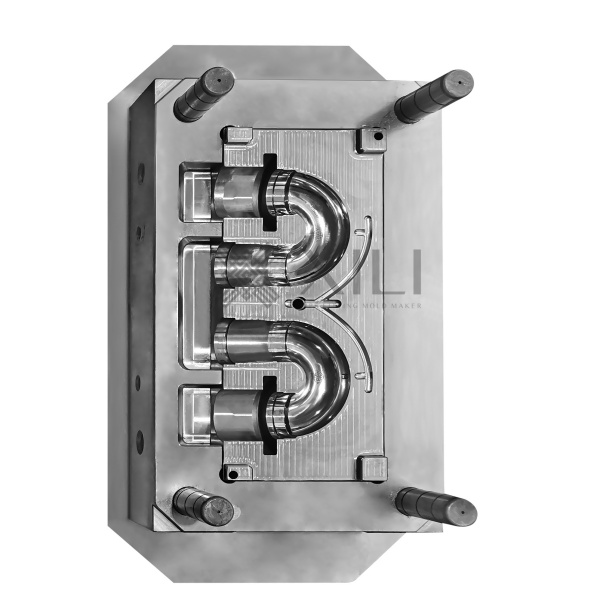

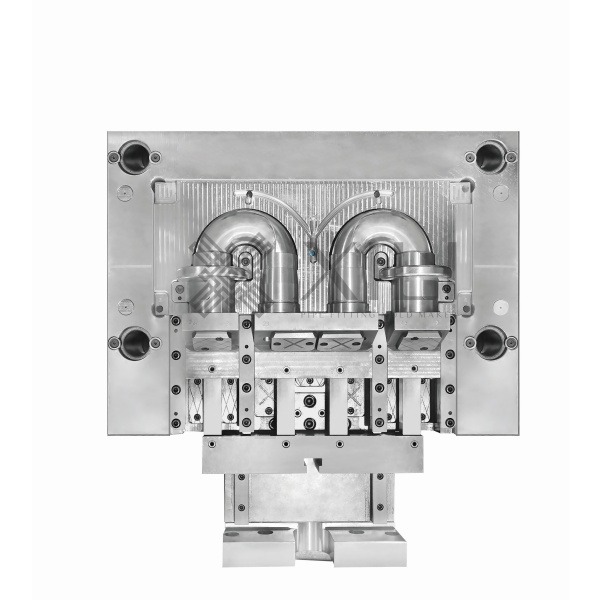

180 Degree U bend Mold

The injection mold used to produce u trap fittings, 180 degree u bend, Ptrap, u trap. The bend allow a full 180-degree directional change in piping systems. These fittings are commonly used in drainage applications. Made from high-quality steel, the mold is taking a unique pulling mechanism, designed for precision, durability, and efficient production.

180 degree bend mold Technical Sheet

| Fitting Product Material | PVC |

| Product Size | 20-315mm |

| Mold Base | HASCO, Customized mold base,S50C/S45C/LKM |

| Mold Core/Cavity Steel Material | DIN 1.2316, S136, 4Cr13,etc 2738,H13,P20,ETC |

| No. of Cavity | According to customer requirement like annual output, injection molding machine size |

| Injection Molding Machine | >>Need injection molding machine special for PVC products. Screw surface processed with hard chrome plating against corrisive. Independent-controlled blowers to control temparature. Enlarged the hydraulic charging motor. >>Matching injection molding machine size with mold cavity and mold size. |

| Mold Structure | Fully automatically |

| Runner | Cold runner / Hot runner |

| Cooling Water System | Unique cooling system for circular cores to improve efficiency. |

| Mold Design Sofeware | CAD, CAM, CAE, Pro-E,etc. |

| Mold Machining equipment | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, drilling machine |

| Mold Surface Finish | Texture (MT standard), high gloss polishing, Mirror finish etc |

| Lead Time | 60 days |

| Mold Life | 500000-1000000 shots according to your working environment |

| Standard | ASTM,GB/T,ISO4435,AS/NZS,DIN…etc |

| Capacity | 300 sets per year |

| Package & Delivery | Molds are packaged with wooden case |

| After sale service | Free spare parts Technical support Rework support |

180 Degree U bend Mold Detail Display

Get Free Quote of 180 Degree Bend Mold

Contact us for more details. We are available to provide a complete turnkey solution.

Related Products

Related News

Providing accurate information when requesting a quote for a plastic pipe fitting mold is essential to ensure the mold manufacturer […]

Introduction This user manual is intended for the proper handling, installation, operation, and maintenance of plastic pipe fitting molds, including […]

Proper maintenance of an injection mold is essential to ensure its longevity, reduce downtime, and maintain the quality of molded […]

Assembling a mold on an injection molding machine is a crucial step to ensure smooth production and high-quality molded plastic […]

Selecting the appropriate mold steel is crucial for producing high-quality plastic pipe fittings while balancing cost, durability, and performance. The […]